We put as much love into our details as we do our designs – which is why our buttons come from Courtney & Co. A champion of the revival of button making in the UK, the company does tradition with a green twist: it only uses natural materials for its buttons, produced with one eye on the environment.

The home of button making

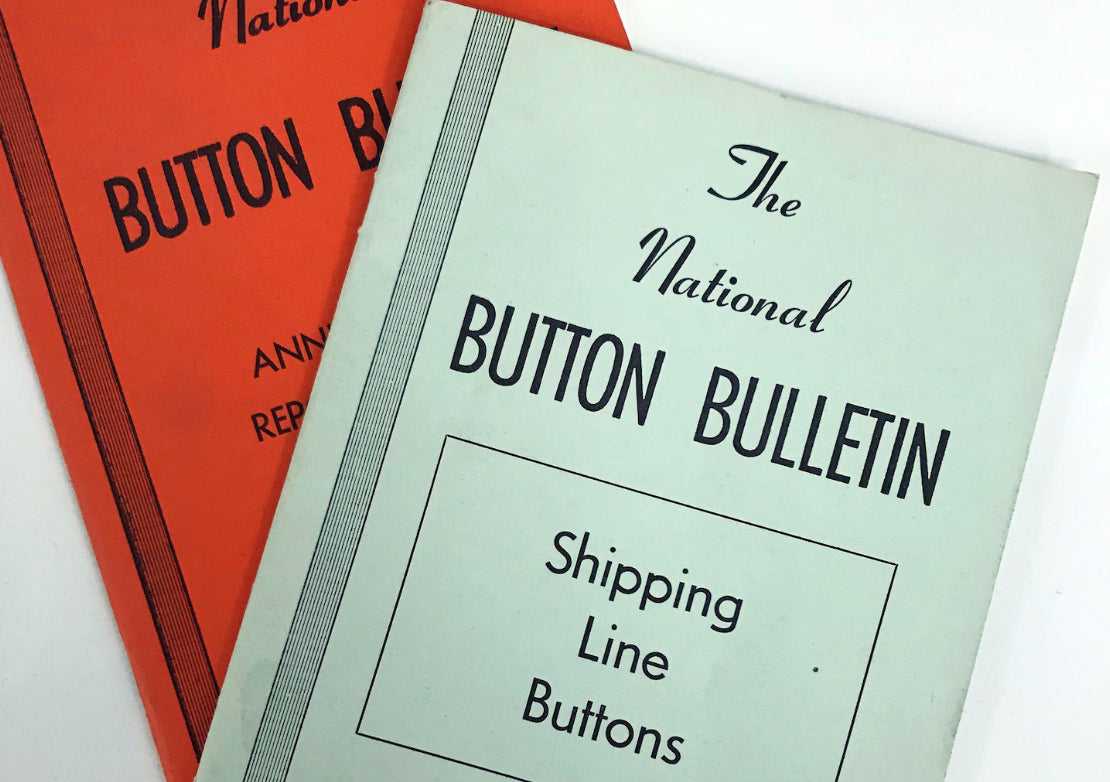

It wasn’t just its eco-friendly ethos or use of natural materials that attracted us to British button maker Courtney & Co: it was also its colourful history.

Although founded in 2016, Courtney & Co is built on the rich heritage of James Grove & Sons, a traditional button maker established in 1857. Back then, Britain was at the heart of button manufacturing, and the company was famed for its quality buttons. Sadly, that wasn’t enough to save it from the effects of globalisation: in 2012, it closed its doors for good. Or so it thought…

Enter David Courtney, a former broker whose interest was piqued by the ailing company’s ad looking for a new buyer. Armed with the romantic vision of reviving a once-thriving industry – and button-making machines bought from James Grove & Sons’ archives – he launched Courtney & Co.

His vision is one we celebrate, not only because we think it’s a brilliant thing to make our industrial past work in the present, but because we can reduce our carbon footprint by sourcing our buttons locally.

Machinery from the factory floor of James Grove & Sons'.

Original button polishing barrels at the James Grove & Sons' factory.

All natural

Most modern buttons are made from polyester. But Courtney & Co prefer to do things the natural way, using corozo or Codelite®.

Corozo is the name of the nut from the Tagua palm, which grows in rainforests in South America. Reputedly, the best comes from Ecuador, which is where Courtney & Co sources theirs. Our Edi shirt and denim styles are made with their corozo buttons.

After planting, it takes 15 years for the Tagua palm to produce its first crop, and even then, it can only be harvested once it naturally falls to the ground, making it a more responsible choice. In addition, the rainforests where it grows are largely protected from deforestation, as it’s such a valuable crop.

The 'mococha', containing the corozo nut.

Codelite® is made from casein, a protein naturally occurring in milk. First produced in 1910 in the UK, production continued until the early 1970s, when polyester buttons became ubiquitous. Now it’s gone full circle, with Courtney & Co reintroducing Codelite®. Robust and hardwearing, its biggest plus is that it’s biodegradable. We chose Codelite® for some of our shirts, so that when your piece reaches the end of its natural lifecycle, its impact on the environment will be lower.

An eco-friendlier philosophy

After harvesting corozo, Courtney & Co’s farmers in Ecuador send leftover pulp to beauty manufacturers to turn into natural microbeads. Outer casings are used locally for fuel; and to offset its carbon footprint created through importing corozo, trees are planted in community gardens and orchards across the UK.

It also uses eco-friendly dyes, and if colours come out incorrectly, buttons are re-dyed in black so they can be reused.

The ideas of zero waste and circularity chime with us, which is why we’ve worked with Courtney & Co’s buttons across our entire launch collection.

1 comment

Beautiful designs and such an interesting piece on buttons. Congratulations!