Every Saywood piece begins with the hands that make it. From East London embroidery to hand-guided corduroy in northern Italy, our garments are crafted by a collective of artisans, makers and mills we’re proud to call partners.

Most of fashion’s environmental impact happens during production, so we choose to do things differently. Local where we can, responsible always and grounded in a deep

appreciation for heritage craft.

We’re honoured to work with many of our makers here in the UK. And while our Founder, Harriet, hasn’t yet visited every fabric mill we work with... she’s been to all our factories and is steadily crossing each mill off the list.

Because how something is made matters. And so do the people who make it.

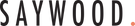

Riopele - Fabric Mill, Portugal

Nestled in northern Portugal, Riopele is where we source many of Saywood’s surplus fabrics - including the fluid, yet structured Lyocell-cotton blend used in our iconic pink tartan Rosa Shirtdress.

But Riopele’s impact runs deeper than the loom. As a STeP by OEKO-TEX Level 3 certified mill, it integrates people and planet into every step of its production.

In 2024, the mill recycled over half its water (saving the equivalent of 150 Olympic swimming pools) and aims to reach 60% by 2027. It runs on 75% green energy, powered by solar plants and a biomass boiler, saving around 2,000 tonnes of CO₂ each year. And in 2022, it recovered 99.9% of its own waste, reinforcing a closed-loop approach to making.

As a Better Cotton Initiative member, Riopele sources fibres from ethically regulated regions that practise sustainable farming techniques requiring fewer pesticides, water and resources. Riopele’s investment supports the initiative’s mission to help cotton communities survive and thrive through sharing farming knowledge and soil-preserving techniques that minimise chemical use and protect biodiversity.

From surplus fabrics that avoid landfills to ethical working conditions and on-site medical support for employees, Riopele is a shining example of the type of makers we find it an honour to work with.

You’ll find its fabrics in pieces like the Rosa Shirtdress and Amelia Culottes - high-quality surplus textiles reimagined into timeless pieces designed to be worn, loved and cherished.

Canclini - Fabric Mill, Italy

Known for its refined shirting cloths and deep-rooted textile heritage, Canclini has been weaving fabrics with care in Como, Italy, since 1925. Today, it’s where centuries-old craft meets future-focused innovation. Sustainability is at the heart of its process, from GOTS- certified cotton to innovative technology that reduces water and energy use.

All of the cotton Saywood uses from Canclini is Supima. It’s grown by a small network of family farms in the US using regenerative techniques like monitoring soil health via satellites and zero-waste harvesting. Its recycled fabrics are Global Recycling Standard-certified, and the mill has its own photovoltaic solar farm - 85% of the energy powers the HQ, while the extra clean energy is fed back into the local grid. Even its dyeing machines are advanced, using up to 70% less water and energy than conventional methods.

Canclini fabrics appear across our collections, from the recycled cotton of our Marie Blouse in pale blue to the cotton-bamboo blend in our Edi Shirt and our rich, premium Japanese Denim collection, woven in partnership with artisan makers in Okayama, Japan.

More than a supplier, Canclini is a partner in our mission to make fashion more thoughtful. Its commitment to traceability, low-impact farming and clean energy helps us craft pieces with not just beauty in mind, but responsibility, too.

Duca Visconti - Fabric Mill, Italy

Few mills in the world still needle-cut corduroy by hand. Duca Visconti is one of them. Every wale (the raised ridges) is guided by human touch, not machine speed. It’s this dedication to time-honoured technique that gives our corduroy its signature softness, richness and depth.

For over 180 years, the Italian mill has specialised in premium cotton and corduroy, crafting cloth with care and precision. And this takes time. While the artisanal needle-cutting technique takes four times longer than industrial methods, the resulting finish is exquisitely refined - and worth the wait.

At Saywood, we work with GOTS-certified organic cotton and cotton-linen blends woven by Duca Visconti for effortless wardrobe essentials like our Amelia Wide Leg Trousers. Its fabrics are OEKO-TEX Standard 100 certified, and every stage - from dyeing to finishing - is done in-house, with a keen focus on environmental responsibility and quality.

For us, working with Duca Visconti means choosing craftsmanship over convenience - and passing that care on to you, in quality pieces that reflect our commitment to slow fashion.

Somelos - Fabric Mill, Portugal

Every shirt starts with the cloth. And at Saywood, that cloth often begins at Somelos, a heritage mill in picturesque Portugal. Known for its crisp, high-quality cotton shirting, it’s what gives our shirts their clean lines and effortless silhouettes.

While Somelos is still on the path toward fully sustainable production, we admire its commitment to meaningful progress. The mill is a member of the Better Cotton Initiative and already offers GOTS-certified organic and recycled cottons, though minimum order volumes mean these aren’t always accessible to smaller independent labels like us (yet).

What makes Somelos stand out is not only its expert fabric know-how but also its openness to collaboration. Our close relationship with the team allows us to work with shorter runs and stock service colours, helping us reduce waste and avoid overproduction while still working with trusted, high-quality mills.

Because at Saywood, sustainability isn’t just about the materials - it’s about the people and partnerships behind every piece.

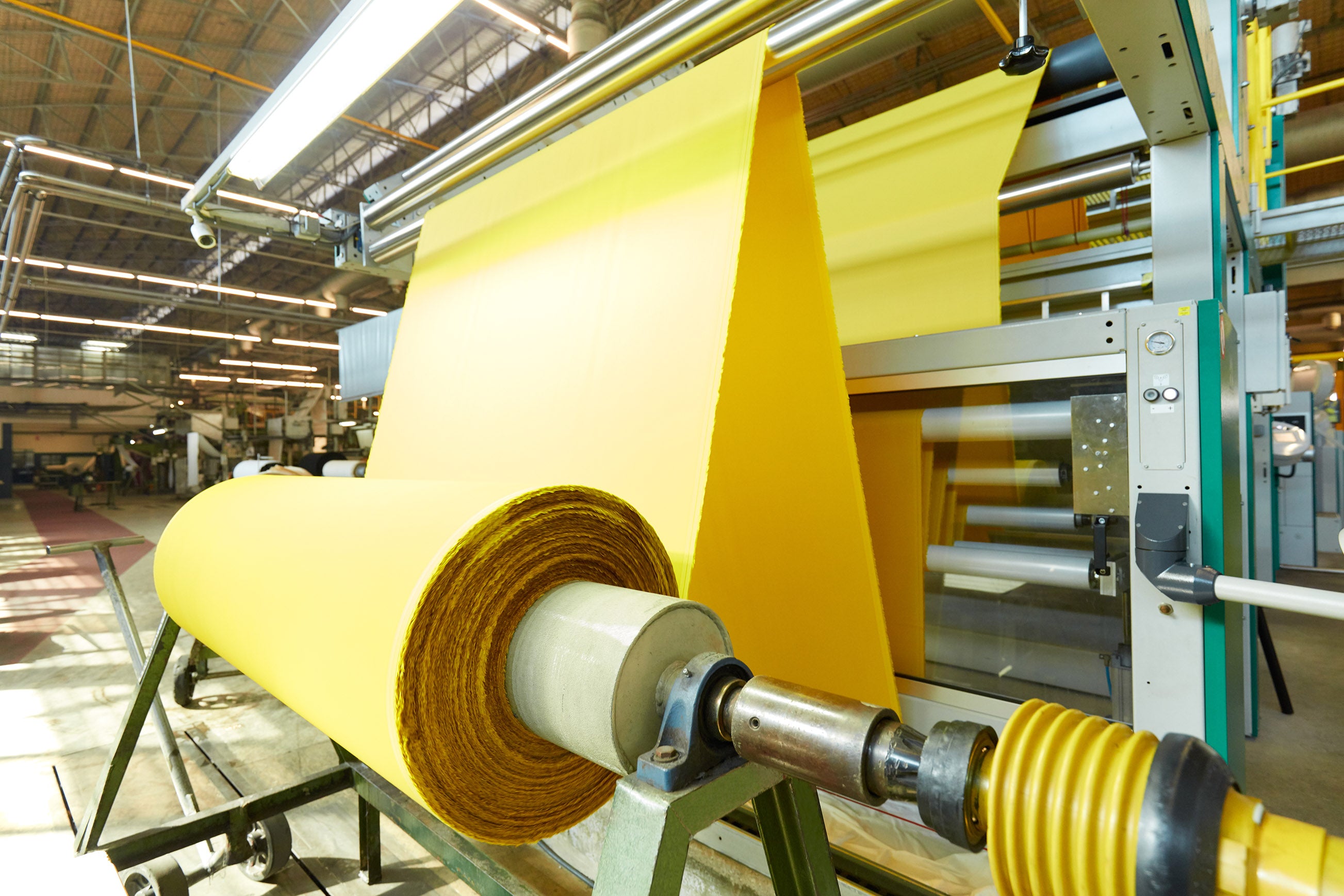

JC Rennie - Yarn Mill and Spinners, Aberdeenshire, Scotland

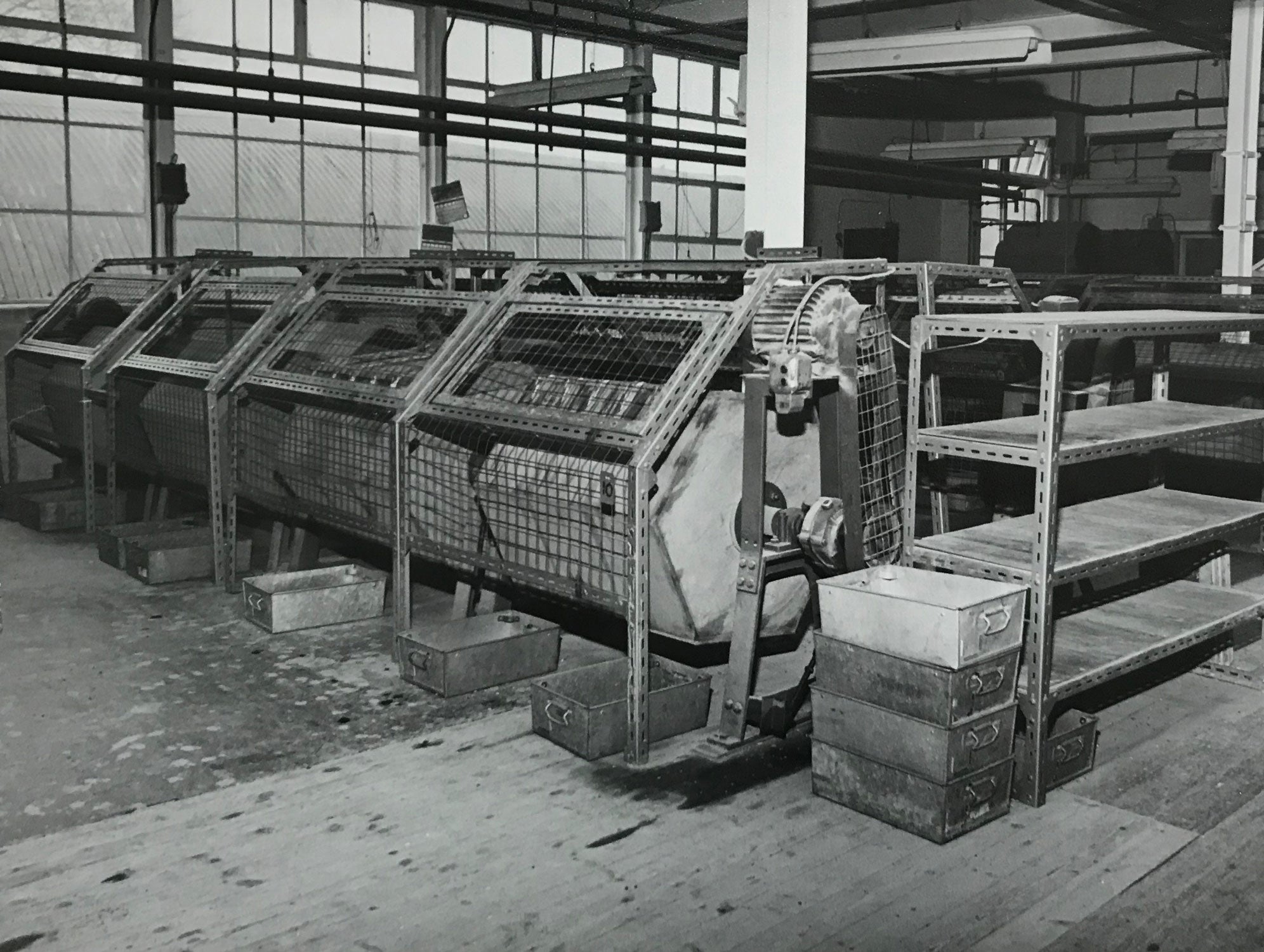

Tucked away in the sloping hills of Aberdeenshire, JC Rennie is one of Scotland’s oldest surviving woollen mills, spinning yarn since 1798. For over two centuries, this family-owned mill has balanced heritage craft with quiet innovation, producing yarns that are as durable as they are comfortable.

Our supersoft 100% lambswool comes from carefully selected New Zealand and Australian flocks, where strong animal welfare laws ensure sheep are treated with utmost respect. Each fleece is typically shorn in the warmer months, keeping the animals healthy while providing a fibre that is naturally renewable, biodegradable and regenerative. Each wool lot is dyed in varying tones before being blended and spun together with undyed yarns. The result is a Shetland-style yarn with subtle colour variance, depth and dimension - the hallmark of a JC Rennie yarn.

Some of the mill’s traditional machinery has been in use for over half a century, lovingly maintained by skilled hands that know the sound of every hum and the beat of every rhythm. This blend of history and responsibility is what makes JC Rennie the perfect fit for Saywood’s first foray into knitwear, helping us create pieces with integrity, texture and timeless character.

Knitster - Knitting Factory, London, UK

Just a stone’s throw from Saywood HQ sits Knitster, a small (but growing), female-founded knitwear studio where technical skill meets creative artistry. With only five machines in the factory - each with a different gauge - production is intentionally small-scale, giving every piece an exclusivity and care that’s hard to replicate.

While the main garment elements are machine-knit, each is finished by hand. Ends are tied, details perfected, and the vines that trace down the sleeves of our jumpers and cardigans are hand-finished to give their leaves a delicate 3D effect. It’s a process that takes time (around 20 minutes per sleeve), but one that transforms our knitwear into wearable art that’s worth treasuring.

We work closely with Knitster’s founders, Emma and Aysen, to bring designs from sketch to stitch. The collaboration ensures every piece, from sweater vests to statement-sleeved jumpers, captures our shared love for the small details, wardrobe longevity and responsible making.

Rooted in London’s rich textile heritage, Knitster champions both sustainability and skill, proving that small factories can make a big impact on the future of fashion.

Apparel Tasker - Garment Factory, London, UK

Good fashion starts close to home. That’s why many of our garments are made just around the corner from our studio at Apparel Tasker, a London-based factory that shares our values of conscious craftsmanship, care for the planet and respect for the people behind every piece.

Working with Apparel Tasker means we can keep our production local, dramatically lowering our carbon footprint while supporting the future of British garment-making. But it's more than just proximity. The team works with purpose, offering higher-than-industry wages, safe working conditions and a commitment to ethical, SMETA-certified practices that protect human rights at every level of the supply chain.

Apparel Tasker uses its high values to keep its energy use low. From biodegradable packaging to energy-saving LED lighting (which saves 70-80% energy compared to conventional lights) and zero-waste processes that turn off-cuts into biofuel to power the factory - everything is taken into consideration to reach its carbon-neutral goal. Even the machines run on high-efficiency motors to minimise energy use. Its approach is rooted in deliberate, sustainable choices, not shortcuts.

Together, we create timeless pieces that are made to last - designed, cut and sewn with intention.

MAES - Garment Factory, London UK

Just down the road from Saywood's studio, a sunlight-filled garment factory in North London stitches many of our designs into being. This luxury studio is MAES - an independent manufacturer specialising in small-batch production where thoughtful design meets premium craft.

Step inside MAES, and it’s easy to feel the difference. The factory is a thoughtful, creative and meticulous space - the kind of place where slow fashion thrives. Every piece is handcrafted by a team of skilled makers who, like us, value quality and attention to detail.

Keeping production close helps us reduce our carbon footprint and maintain the highest standards of quality while supporting British manufacturing. MAES loves working with natural fibres and follows a considered, low-waste approach to making. Its commitment to sustainability is rooted in a deep sense of responsibility, from fair wages and ethical working conditions to preserving local craft. Everyone involved is treated with care and respect, just as the garments are.

We choose to work with MAES not just for how they make, but why. It’s a partnership built on a shared belief in doing things beautifully and responsibly (plus, we love popping in for regular visits). Together, we create some of your favourite pieces, including the Amelia Trousers, Bessie Shorts and Rosa Dresses.

Mantra - Garment Factory, Romania

We believe in giving opportunities to manufacturers who genuinely want to change their working practices for the better. Mantra, based in Romania, is one of them.

To date, it has managed to eliminate nearly four metric tonnes of new polyester from being produced, thanks to its switch to recycled polyester. By 2021, it is aiming for all linings, labels and packaging to be made from recycled polyester. Its other focus is carbon neutrality, by recycling waste into materials for padding.

Mantra shares our ethical values, with clean and safe working conditions and high wages. Garment construction is highly skilled, meaning their workers are paid well above the living wage.

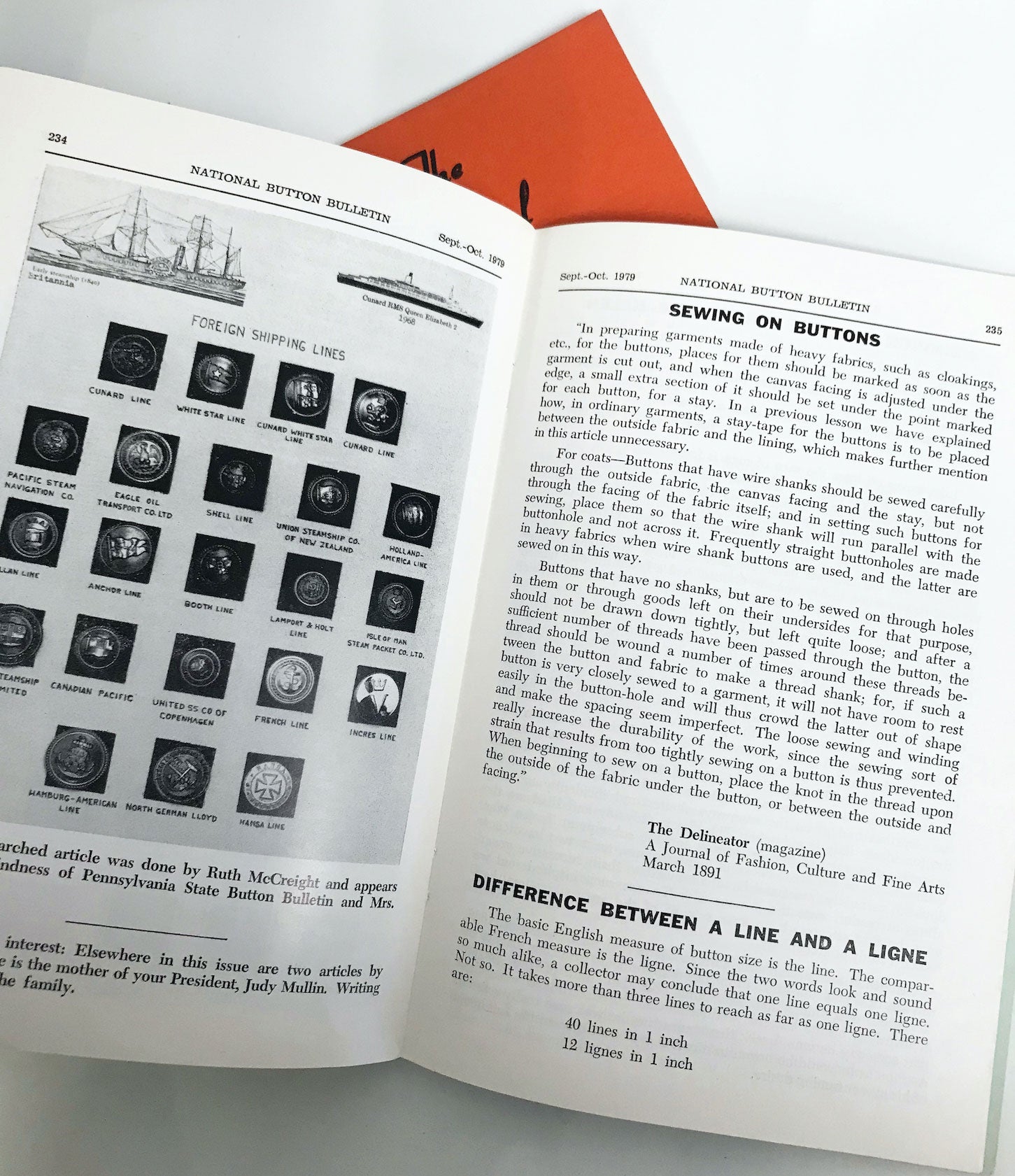

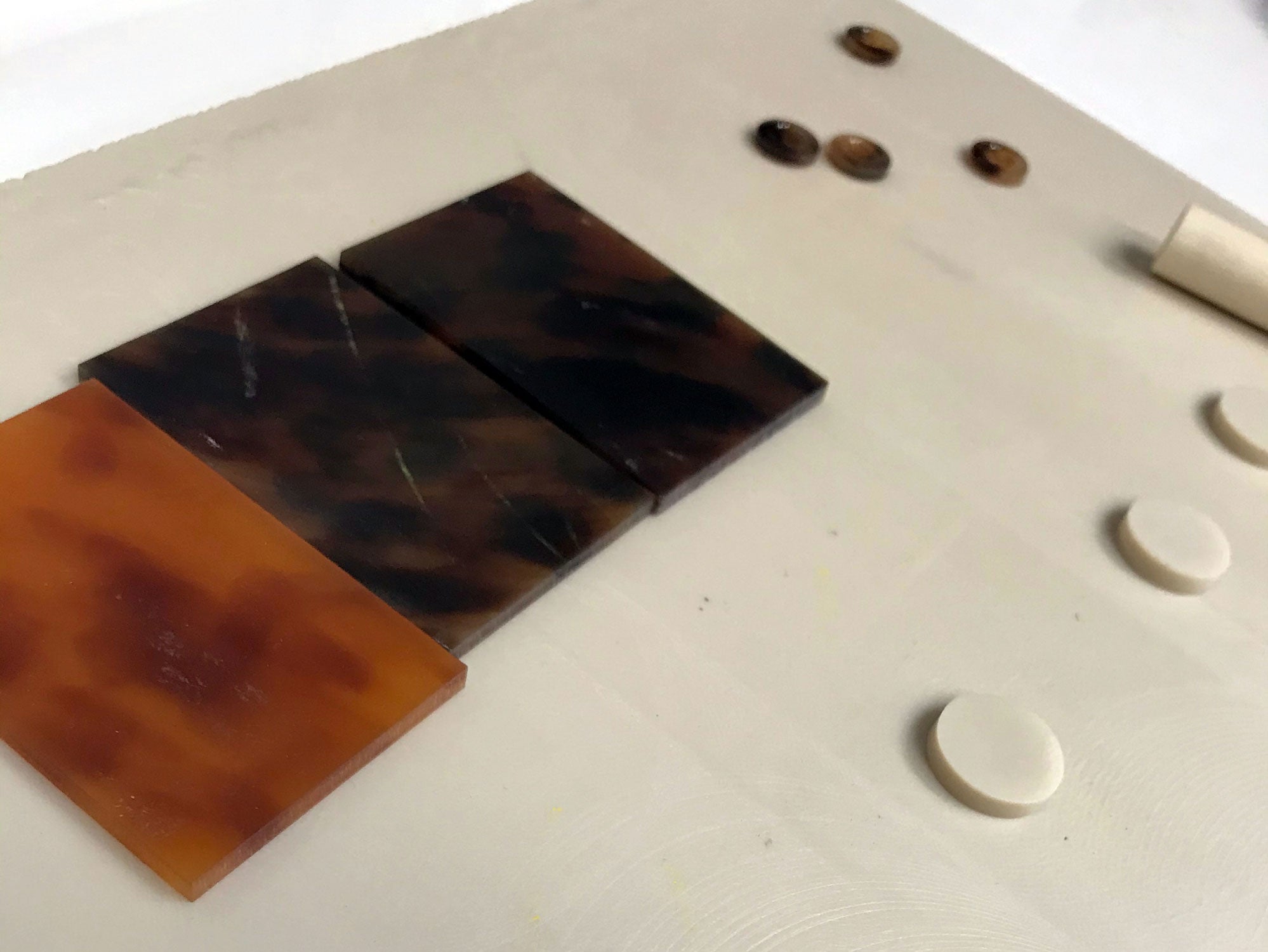

Courtney & Co. - Button Makers, Gloucestershire UK

In the quiet hills of the Cotswolds, a once-lost craft has been revived: the art of British button-making.

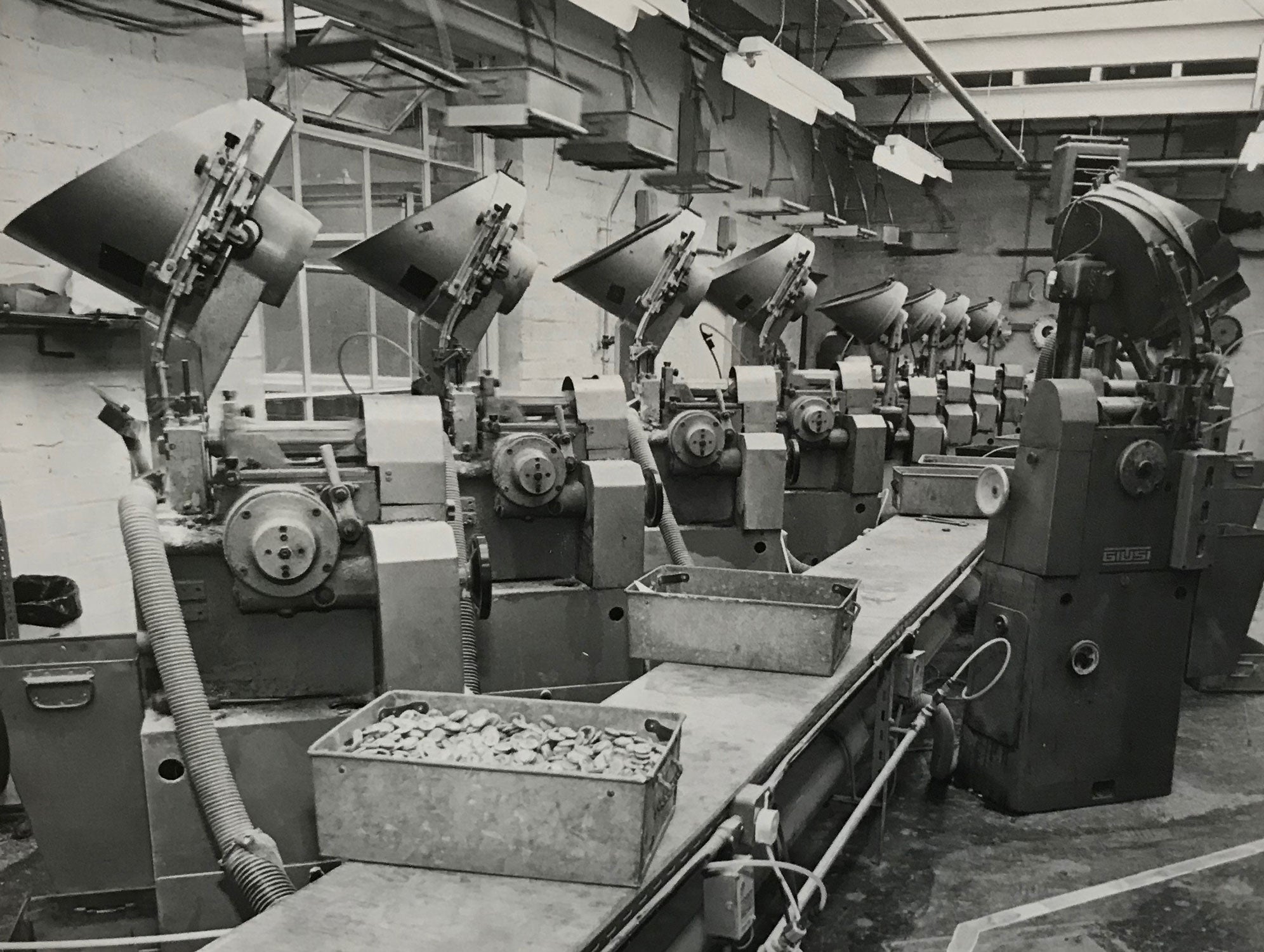

Despite crafting some of the smallest details in our collections, our heritage button maker, Courtney & Co., has one of the biggest stories. When the last major natural button factory closed in 2012 after 155 years, it marked the end of an era. But founder David Courtney saw a chance to bring it back. Acquiring the last remaining machines (and with them, the spirit of a legacy industry), he set out to restore traditional button-making in the UK, one button at a time.

Each button is made using natural materials and time-honoured techniques. We use Codelite®, a casein-based material made from milk protein, and corozo, the nut of the tagua palm, which is only harvested when it falls naturally to the forest floor like a quiet gift from nature. These buttons are durable, biodegradable and far superior to plastic alternatives. You’ll find them on Saywood staples like our Edi Shirts and Bessie Shorts.

Courtney & Co. embodies everything we value: sustainability, transparency and a deep respect for craft. From eco-friendly dyeing to upcycling corozo waste into microbeads for natural beauty products, every stage is designed to tread lightly. And, by keeping production local, it helps preserve traditional British skills and reduces the environmental cost of every finished piece.

These aren’t just functional buttons; they’re a return to heritage, bringing intention and purpose back to the smallest of details.

Echo3 - Embroidery Studio, London, UK

Embroidery is one of the oldest forms of textile storytelling. We partner with Echo 3 to bring this craft of precision and permanence to our pieces in a way that feels both personal and contemporary.

Based in East London, Echo 3 is a small but highly skilled studio where tradition meets thoughtful creation. Born from a childhood spent among the hustle and bustle of factory floors and family-run workshops, founder Abid’s vision is a modern continuation of the area’s rich legacy of hands-on making.

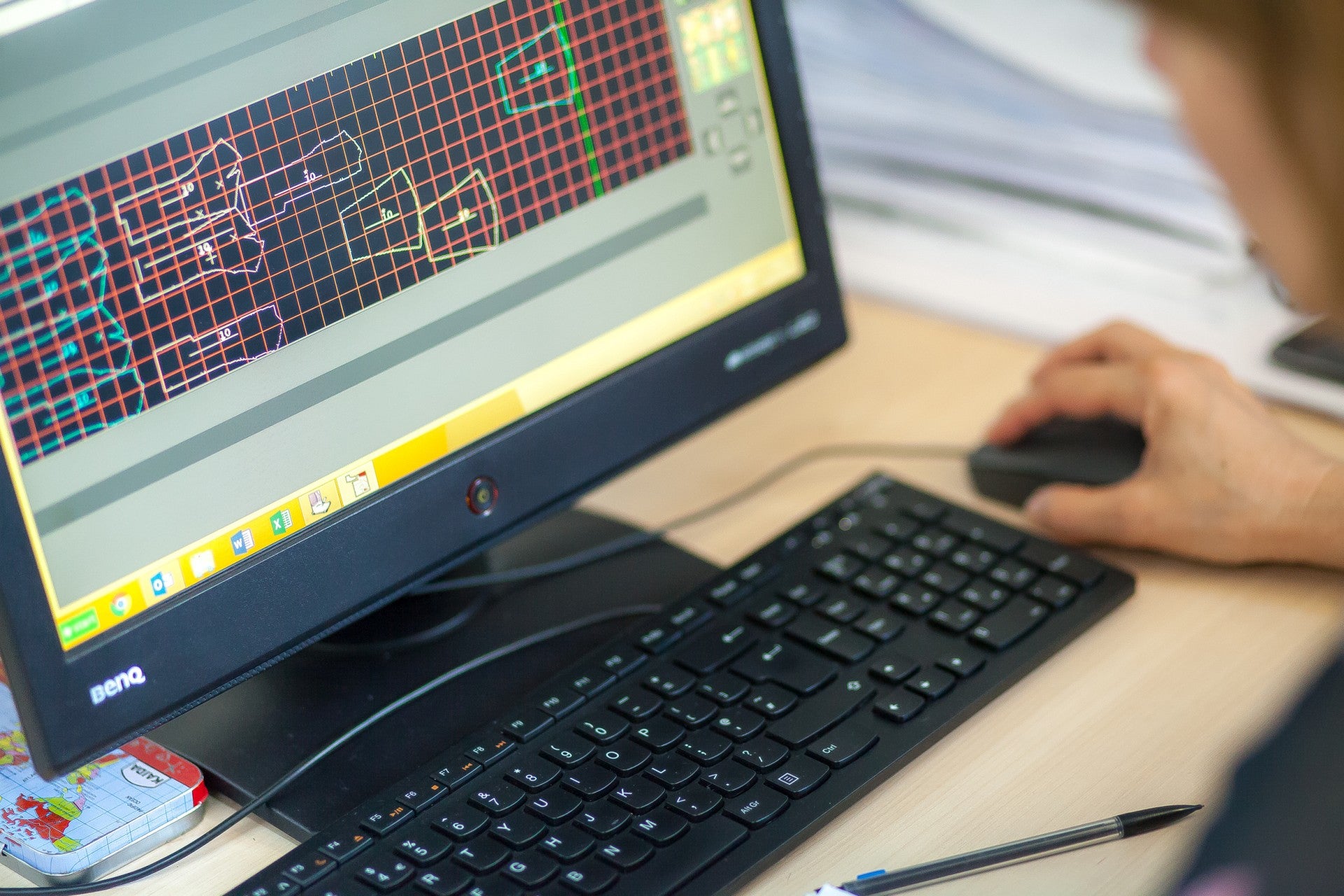

The studio blends vintage and state-of-the-art embroidery machines, allowing for intricate, bespoke details alongside larger-scale production. From the placement of a petal to the sweep of a stitch, every design is crafted with care and intention.

To stitch our iconic Saywood flower, Echo 3 uses OEKO-TEX Standard 100 certified rayon viscose thread sourced from FSC-certified forests. It's free from harmful chemicals while maintaining a rich colour, premium finish and long-lasting durability. Just like our elevated pieces, our embroidery is designed to be worn, loved and cherished season after season.

Freiba Trims - Germany

From trims to lace, every element is thoughtfully designed, down to the last detail. That's why we work with partners who also honour craft, quality and caring for people and the planet.

In Germany, we source our trims from Freiba, a trusted, family-run business with over a century of expertise. Its collection is OEKO-TEX Standard 100 certified and includes GOTS-certified organic cotton options, with a growing focus on renewable and recycled materials. Crafted with a belief in timeless quality, paired with modern responsibility, Freiba’s lace trims and cotton herringbone tape are a natural fit for Saywood.

Rebil Labels - Turkey

For our labels and hang tags, we work with Rebil, a small studio in Turkey with a considered, low-impact approach. Our back neck labels are made from recycled polyester (the only bit of synthetic material you’ll find on a Saywood garment), chosen for its colourfastness and durability that outperforms printed cotton labels.

Our care labels are made from cotton so soft you won’t even feel they’re there. And, our hand tags are crafted from recycled paper, finished with biodegradable, unwaxed cotton string that can be pulped and reused - staying in line with our zero-waste ethos.

When we say we’re all about the details, we mean it. It’s why we carefully choose partners who find beauty in the smallest things and responsibility in every part of the process.